What is an Exothermic Reaction?

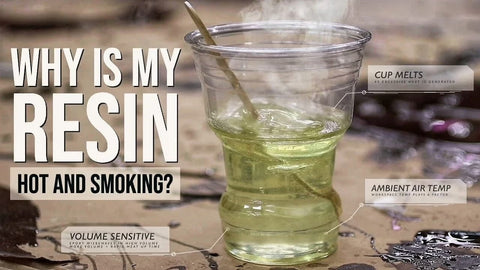

If you found this post, you probably had this experience! You look over and see your epoxy resin smoking or maybe your mixing cup melted. When you mix Part A (resin) and Part B (hardener) together new chemical bonds begin to form causing an epoxy exothermic reaction. Energy is released in the form of heat as the mixture catalyzes.

Why does resin get hot?

Often the term “exotherm” is used when epoxy gets very hot, bubbles, smokes or cracks, however exotherm isn’t just a bad side effect. Exotherm is an integral part of epoxy resin chemistry and some heat or exotherm is required for the mixture to solidify and properly cure. With that said, epoxy resin is temperature and volume sensitive. So the higher the ambient air temperature and volume of epoxy used; directly corresponds to the amount of heat generated. To solve this problem, we developed MAS Deep Pour that can be applied 1 inch thick! We also developed MAS Deep Pour X, which can be poured 2 inches thick.

Why Epoxy Can Overheat

-

The layer is too thick

Each epoxy resin system has a “safe” pour depth at room temperature. If you exceed that depth the transfer of heat becomes problematic. If exceeded as the chemical reaction “kicks off” the amount of thermal mass exceeds the thermal transfer rate generating excessive heat. -

The ambient air or shop temperature is too hot

If you live in a warm climate, it’s recommended to cool the space you’re working in or wait until air temperatures have dropped before pouring epoxy. Air temperature corresponds to the thermal transfer rate, for example, if the air is 95F and epoxy is already at 90F when pouring the reaction will generate even more heat and the working time will be significantly reduced. -

The material or mold doesn’t transfer heat adequately

Take into consideration the insulating properties of the materials you are using. If the piece retains heat the epoxy temperature will also increase. -

The epoxy was warmed before pouring

If you work in a cool environment and need to warm the epoxy to mix properly, make sure you spread the epoxy over the surface versus letting it sit in the mixing container for any duration. If the epoxy is already heated it will accelerate the chemical reaction. -

The previous layer hasn’t cooled before applying another

If you are doing multiple layers or step pouring, make sure the prior layer has cooled back down to room temperature before applying the next layer. Heat rises and the top layer could overheat if the prior layer still gives off heat.

How to Prevent Epoxy Exotherm or at Least Mitigate It

-

Mix only what you need

Epoxy sitting in mass will exotherm more than epoxy that is spread out. To prevent issues with a hot cup only mix what you need at the time and in small batches until you’re used to the way the system works. If you see your epoxy resin overheated in the cup or beginning to do so, pour it in a thin layer to slow down the exotherm. -

Thin or shallow pours

There are many factors to consider with large pours. If you are pouring a high-volume area it’s better to be safe than sorry. Our Deep Pour epoxy resin has a max depth of 1” but every situation is different. If the volume exceeds 1 gallon it’s advisable to pour a thinner layer so the heat can transfer off rather than continue to heat the entire area. Remember when choosing an epoxy for casting the shorter the gel time, the less you can pour at once. -

Cool the workspace

If the piece seems to be warming up rapidly and you fear you’ve gone a bit too deep, you can try cooling the area. It may be as simple as opening a door or blowing air over it or under it with a fan. Just keep in mind with airflow you can easily introduce dust and other airborne particles into you pour. The gel time specified on your data sheet is at a certain temperature and mass. It’s good to know that doubling the mixed mass specified will likely cut your gel time in half. If you increase the temperature by 18F (10C) you will also cut the gel time in half. Mass and temperature matter. -

Practice makes perfect

If it’s your first time working with epoxy resin, do a few small test runs to get a feel for the chemistry and what will transpire in different depths. Keep in mind that each epoxy resin system is different, and they vary greatly from brand to brand. If you’re very comfortable with one system, then switch to another take the time to learn the differences so you can have a successful pour.

Check out the Video Explanation

Important to know:

The gel time specified on your data sheet is at a certain temperature and mass. It’s good to know that doubling the mixed mass specified will likely cut your gel time in half. If you increase the temperature by 18F (10C) you will also cut the gel time in half. Mass and temperature matter. The opposite is true as well. Reducing the mass by 1/2 will give you twice the gel time or decreasing the temperature by 18F (10C).

In the video, we showed a mixture of LV resin with Fast hardener to get exotherm quickly since it has a fast gel time.

Need a Casting Resin?

Sick of exotherm ruining your projects? Try Deep Pour. It can be poured up to 3x as thick as standard tabletop epoxies and cures clear. Or add pigment to make it uniquely yours. Deep Pour X can be poured even thicker than Deep Pour and has a convenient 2:1 mix ratio.

Comments (0)

There are no comments for this article. Be the first one to leave a message!