If you ever have an issue where the epoxy remains soft and sticky on the surface 24 hrs after applying, the epoxy has not cured. Uncured epoxy is the result of a few common mistakes most likely caused by the following.

1. Not Mixed Thoroughly

Epoxy needs to be thoroughly mixed for it to cure correctly. Follow the instructions and use the correct mix ratio for the epoxy you are using. Mixing by hand is the most common method and you need to ensure the epoxy is thoroughly mixed. 2-5 minutes is recommended depending on the volume that is measured. If you see striations in the material you need to continue to mix until they are no longer visible. Be sure to scrape the sides of your cup to ensure proper mixing. For larger volumes of epoxy, it may take longer to mix by hand and for mixing 1 gallon material or more we recommend using a power drill with mixing paddle attachment on low-medium speed to ensure proper mixing.

2. Incorrect Mix Ratio

Most common issue of epoxy not curing is by not using the correct mix ratio. Epoxy Resin is a two part system that requires the correct amount of Part A and Part B to be measured at the correct mix ratio whether it’s 5:1, 3:1, 2:1 or 1:1. If measured and mixed correctly the epoxy will cure 100% of the time. If you have poured a surface and did not mix thoroughly, you may have some spots that cured and some spots that are still soft. If you have a very sticky and soft layer that is able to be moved around after it should be cured, this is due to incorrect mix ratio and most commonly seen by adding more resin than hardener or vice versa. Epoxy Resin should always be mixed thoroughly in a cup by combining Part A Resin and Part B Hardener. If you were to pour resin onto a surface and then hardener without it being mixed together prior to pouring, the epoxy will not set up properly.

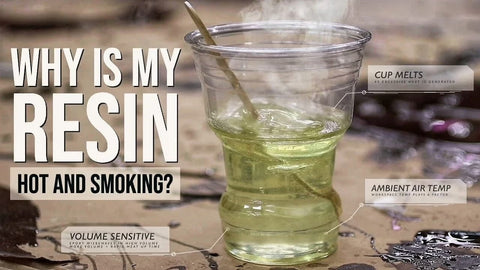

3. Working Conditions

Epoxy is temperature sensitive material. In order for epoxy to cure properly your working conditions need to be around 65-80F. Warmer temperatures will cause the epoxy to cure faster and cooler temperatures will cause the epoxy to cure slower. Temperatures below 60F will stall the chemical reaction of the resin and hardener and not cure correctly.

To learn more about reasons why your epoxy might not be curing check out our blog post and video dedicated to why your epoxy is soft and sticky.

How to Remove Uncured Epoxy?

It is very unfortunate to see but it is fixable. Applying properly mixed epoxy over the existing uncured layer will not solve the problem. You will need to take denatured alcohol, paint scraper/squeegee, chisel and mallet to remove the uncured layer. Once you find a soft spot you need to dig your tool into the surface layer and start scraping it off. Denatured alcohol will help keep your tools from getting very sticky and will need to clean off the tool using to remove the epoxy frequently. This is a tedious process but try to remove the uncured epoxy to the best of your ability. Once all uncured material has been removed, clean the surface with denatured alcohol. Once surface is clean measure and mix your epoxy at the correct mix ratio provided in the instructions of your product. Once measured and mixed thoroughly, pour epoxy onto surface and spread evenly. Apply heat using a torch or heat gun to eliminate air bubbles and let epoxy fully cure. Repeat this process until you get the desired finish you are happy with.

Video Tutorial

Comments (0)

There are no comments for this article. Be the first one to leave a message!