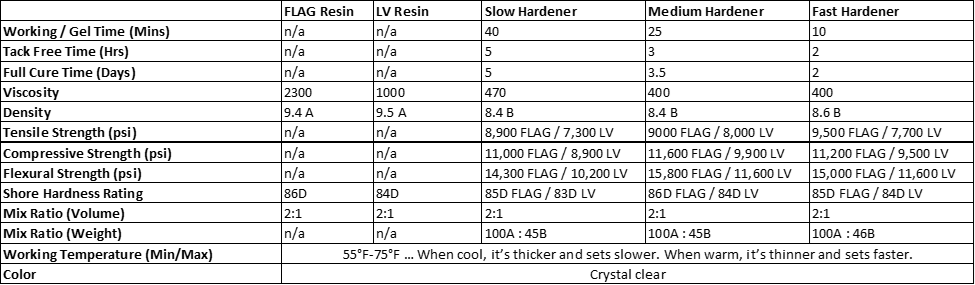

MAS Low Viscosity (LV) Resin with MAS Fast, Medium or Slow Hardeners is a non-blushing, low viscosity, low odor epoxy resin system. It can be used for laminating, filleting, and gluing. It has a simple 2 to 1 by volume mix ratio, easily wets out fiberglass fabric and requires no messy washdowns. MAS Fillers such as phenolic microballoons, colloidal silica or wood flour may be added to the epoxy resin to make compounds for bonding, fairing, filleting, or filling. LV Resin can be combined with FLAG Resin to create a custom viscosity resin. Fast, Medium and Slow Hardeners can be combined to create custom gel times.

- Easy to use 2:1 mix ratio by volume

- Non-blushing system that requires no messy wash downs between laminations

- Choose between three hardener speeds or mix them for custom gel times

- Formulated as a wood epoxy resin, but is compatible with a range of substrates

- Easily laminates large areas of fiberglass or carbon cloth when paired with Slow Hardener

- Ideal for saturation coating because of self-leveling properties

- Low viscosity epoxy is compatible with vacuum bagging applications

- Excellent sealant when used without fiberglass or carbon cloth

- Clear finish means you get the structure and finish you want with one product

Wood Epoxy Resin

Low viscosity resin has great results with any wooden project because it was originally designed for wooden boat building. Combined with any of the non-blushing hardeners you get the benefits of beauty and strength all in one application. LV is sent out with each Chesapeake Light Craft Kit and used by Sam Devlin in his design-build projects. It isn’t just for boat building though, you can use Low Viscosity resin for furniture, woodworking and even wooden artwork.

Check out some of our project images to see the end results you can get when using Low Viscosity Resin.

How Much Will I Need?

What are the dimensions of your project?

Volume of your project

Cubic Inches72

Cubic Feet0.04

Amount of epoxy resin you will need

Ounces39.89

Liters1.18

Gallons0.31